The pros and cons of the coating quality, in addition with the quality of the paint itself is good or bad, and the level of construction technology have great relationship, in order to ensure the construction quality of lacquer must correct construction process and correct construction methods, and require the construction personnel strictly according to the requirement of process in construction.

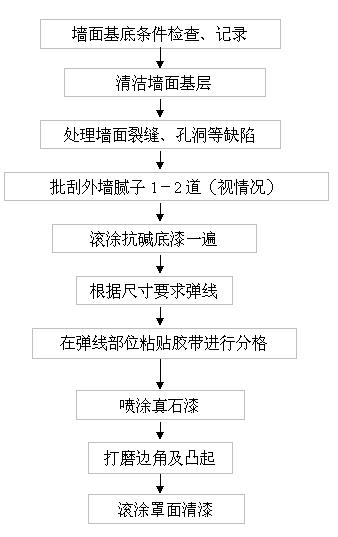

A stone, construction process

Choose a comfortable bed and rest assured of the manufacturers

Two, external wall construction tools

1, in order to ensure the construction quality, it is recommended to use scaffolding group the special lacquer putty scrape Reuse Construction baskets containing sand paint, lacquer and cover varnish.

2, air compressor: power 5KW above, the air volume is sufficient, the pressure is 0.5-1.0 MPa air compressor with three trachea, can meet the construction of more than three people, can automatically control the pressure.

3, spray gun: on the pot of spray gun, capacity of 500ml, diameter 4-8mm; capacity is too large, the operation is inconvenient; the diameter is small, the construction speed is slow.

4, a variety of caliber nozzle: 4mm, 5mm, 6mm, 8mm, etc., the smaller the diameter of the spray is more uniform, large diameter, the greater the cost, the higher the sense of concave and convex.

5, rubber tube: oxygen tube, diameter 8mm.

6, brush, roller, blade number.

7, covered with tools: plastic cloth, fiber board, pushpin, tape.

Three, exterior wall construction technology

(1) basal conditions and treatment

1, primary voids should be filled, sag, repairing and leveling;

2, base has a protrusion and a prominent position, should be eradicated and leveling;

3, there are surface and sticky dust from the primary pollutants should be cleaned, floating, grinding, ensure clean surface;

4, the basic level of oil, should take the cleaning agent for cleaning, ensure the removal of the surface clean and dry;

5, there should be opened to the grassroots hollowing, eradication, and polymer mortar repair;

6, there are cracks and cracks in the grass roots, to deal with the crack and crack to crack and enhance the treatment;

7, there are basic and serious phenomenon of salting out Fanjian, should use oxalic acid neutralization treatment;

8, the breeding place, the application of bleaching powder water repeatedly scrub, and then tap water and steel wire brush to clean the walls clean, completely dry before applying primer.

Choose a comfortable bed and rest assured of the manufacturers

9 and on the walls of the old coating must confirm its adhesion to construction. Otherwise, it must be eradicated first; old wall hollowing, parts of the shell should be eradicated patch formation.

The basic requirements

1, firmly without hollowing, cracking, sand, powder etc.;

2, flat - with intermediate or advanced standard plastering;

3. Dry dry moisture content <10%;

4. The pH value of medium pH <10;

5, clean and free of grease, dirt, mildew, algae etc.;

6, its - hole and damage has been repaired;

7, exposed iron parts have been carried out anti rust treatment;

8, grassroots with construction norms "building finishing construction and acceptance specification" (JGJ/T29-2003) requirements.

(2) the leveling layer construction putty

1, in order to ensure the bond strength of lacquer layer, the proposed use of lacquer of special putty, putty as grass-roots flatness and Yin and yang angle vertical scraping 1 - 2 times, batch after scraping putty need polished smooth and proper maintenance. Proposed construction on the scaffold;

2, the theory of the dosage of 1.5-2.5kg/m2, because the surface condition of different dosage of putty may differ;

3, before a putty dry rear can batch scraping a putty, the focus of attention, yin and Yang, scaffolding joint angle and joint putty scraping.

4, putty scraping, such as grass has thermal insulation mortar, thermal insulation mortar layer should be completed, and the moisture content, standard basic maintenance;

5, in the actual operation, to cover the substrate for standard uniform coating.

6, a putty layer after grinding, in accordance with the requirements of maintenance, putty layer water rate is less than or equal to 10%, pH is less than or equal to 10; 7, check the basal layer, local repair.

(3) the construction of closed primer

1, primer before construction and requirements of grass-roots water rate < 10%, pH is less than or equal to 10; 2, in order to ensure consistent cover primer for more than 10% - 15% water dilution, dilution with clean water can be, after dilution should fully stir evenly.

3, primer general construction again, the construction of uniform, no rolling brush marks, no leakage, the construction requirements of the same color.

Choose a comfortable bed and rest assured of the manufacturers (4) bullet points

1, a large area of the wall proposal as separate small construction area, such as design into imitation brick, imitation stone effect, can avoid lacquer marks, uneven, cracking and other issues.

In 2, a good primer dry wall, remove the dust. According to the requirements of the design size of the elastic line, at the same time to take into account the width of the slit.

3, when the line to determine the level of the first horizontal, vertical direction of the baseline, and then based on the reference line and so on, to ensure that each line is horizontal and vertical. A reference line is recommended every three layers.

4, the elastic line should be clearly visible, the proposed use of different colors to show the primer.

(5) adhesive tape key points

1, in the elastic line of adhesive tape.

2, paste the attention each tape should be online on the same side, such as the vertical line on the left side of the upper horizontal line. Horizontal and vertical.

3, adhesive tape should timely according to the tight solid, in order to prevent the wind from blowing off, a bonding area should not be too large, limited to meet the timely construction area.

(6) the middle points of lacquer spraying

1, lacquer construction shall be maintained in a uniform film thickness, amount per square should match more than the prescribed dosage, avoid film thickness a, significant number of scratch marks or Jiecha, yin and Yang Jiao Dui material conditions.

2, lacquer construction must be in sunny weather, more than 10 DEG C higher than base temperature, humidity less than or equal to 80%, wind < 5 under construction, overcast and rainy days, the wet haze weather, strong winds weather is strictly prohibited construction.

3, lacquer construction should be the hanging basket construction, according to the specified batch construction in the specified wall to avoid different batches of mixed in with a wall.

4, construction interval should pay attention to sealing, due to the hue of lacquer is determined by natural color, because each batch of lacquer color may be slightly different; construction of each batch of material is best separately stacked and separated from the construction, the same wall must be the same batch of product construction, lest cause color, if more than one batch, be sure to in front of the wall to compare, again big area construction; scaffolding supplement hole should be using the surface with a group of materials.

5, try to spray products delivery, and no significant difference between the color and the construction effect and model.

6, workers need unified construction techniques, the strength and the way, with a wall suggested using the same team construction, avoid artificial difference.

7, various proposals two times spraying, again uniform rendering, again making other.

8, the same facade is recommended for a one-time completion, to avoid long-term construction caused by the old and new color.

9, the use of a certain thickness and width of special textured paper, without the use of common masking paper, tear in addition to textured paper to in a timely manner to avoid flash.

Choose a comfortable bed and rest assured of the manufacturers(7) repair side corner points

The dry and hard lacquer to be (general about 72h), using 400-600 sandpaper, gently smooth really stone paint on the convex surface sand material and burr angle, avoid force excessive. Grinding burr, repair parts and parts through the end joint off, and clean the surface.

(8) the construction of the cover varnish

1, the construction of the base temperature of not less than 5.

2, must be lacquer dry, can finish on.

3, finishing varnish not diluted with water, to prevent flooding, not a white, shiny.

4, finish collecting roller direction needs to be unified, avoid the gloss difference caused by the difference of direction.

5, after the construction finishing varnish, lacquer surface color should be consistent, Hikaruzawa Junchi, no, the phenomenon of white hair.

Four, matters needing attention in the construction of lacquer

1, in order to prevent the spraying construction of doors and windows without spraying parts to cause pollution, spraying before the construction of the site do not need to spray the use of plastic sheeting, color of the cloth, paper tape covered paste.

2, during construction in rainy season, wall construction to be elected after the completion of the construction of roof drainage, construction should have corresponding rain water erosion measures.

3, winter construction, construction of indoor and outdoor ambient temperature should be guaranteed in more than 5 DEG C, doors and windows should be closed; outdoor construction should be selected in the noon construction at the same time surface should have wind facilities; snow, high winds, such as bad weather to prohibit construction.

4, according to the size of the engineering quantity, real mineral varnish should be for the same batch of product, a procurement in place, should avoid and minimize the color difference of different batches of products.

5, spraying lacquer construction should the simultaneous construction of hanging basket from top to bottom, as far as possible not to use scaffolding, to avoid leakage and spray gunning chromatic aberration and the joint trace.

6, after the use of spray tool, should be cleaned or immersed in water, in order to prepare for the next use.

Choose a comfortable bed and rest assured of the manufacturers

|